Wildcard Week

For this week, I will try a mixture of digital fabrication techniques to achieve a final product. For this, I will start by 3d printing a mask. I used the Foundry Team original design, and edit its size and some minor details in order to be able fit my face.

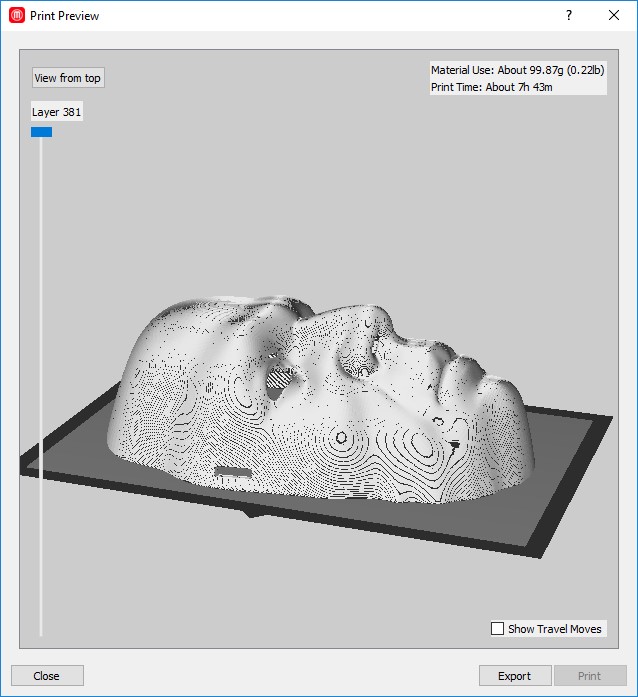

Now, Im ready to print it. I sliced it with 0.2mm, 10%infill and 3shells, and no support, and the estimate time for the print was 7hours and 43 minutes.

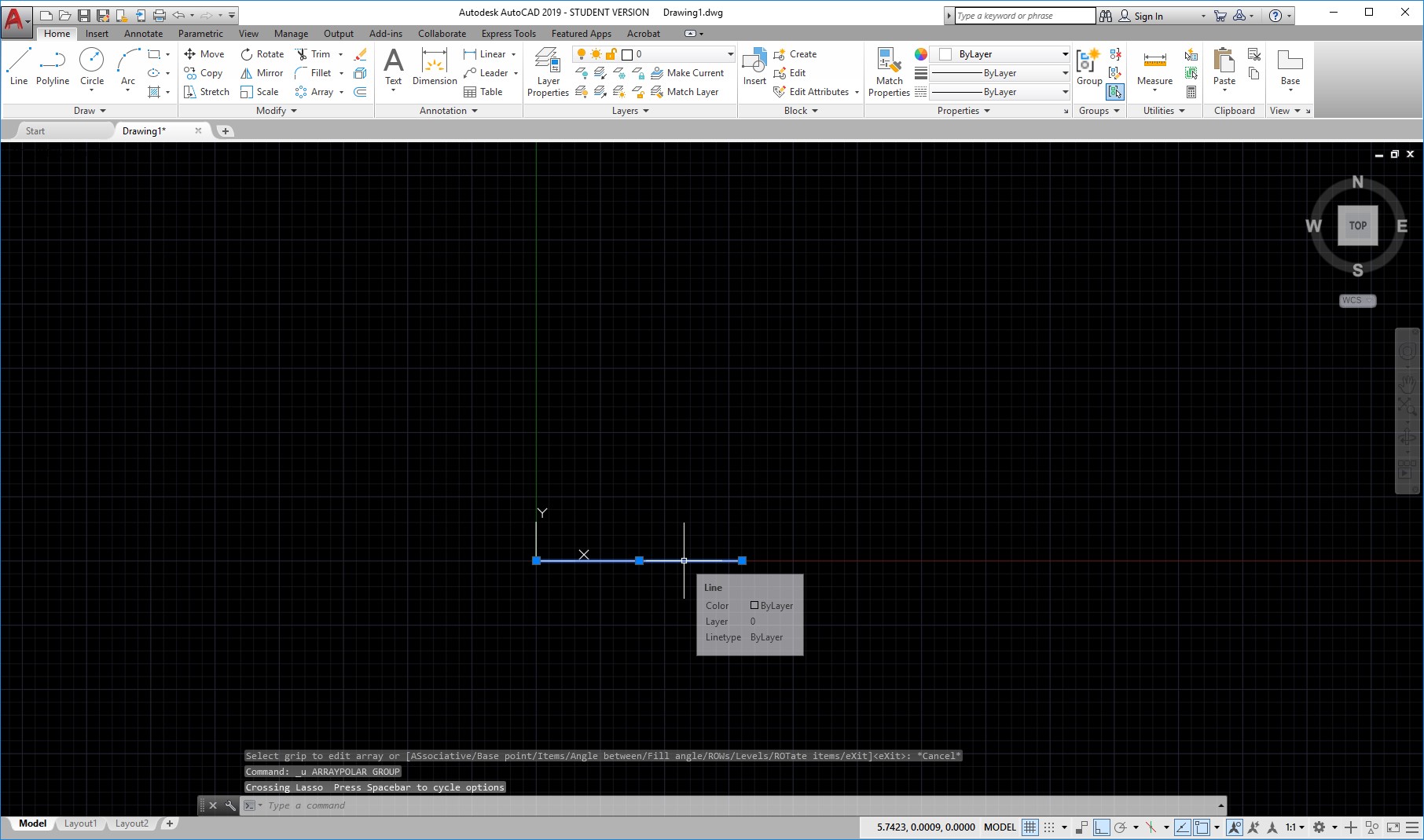

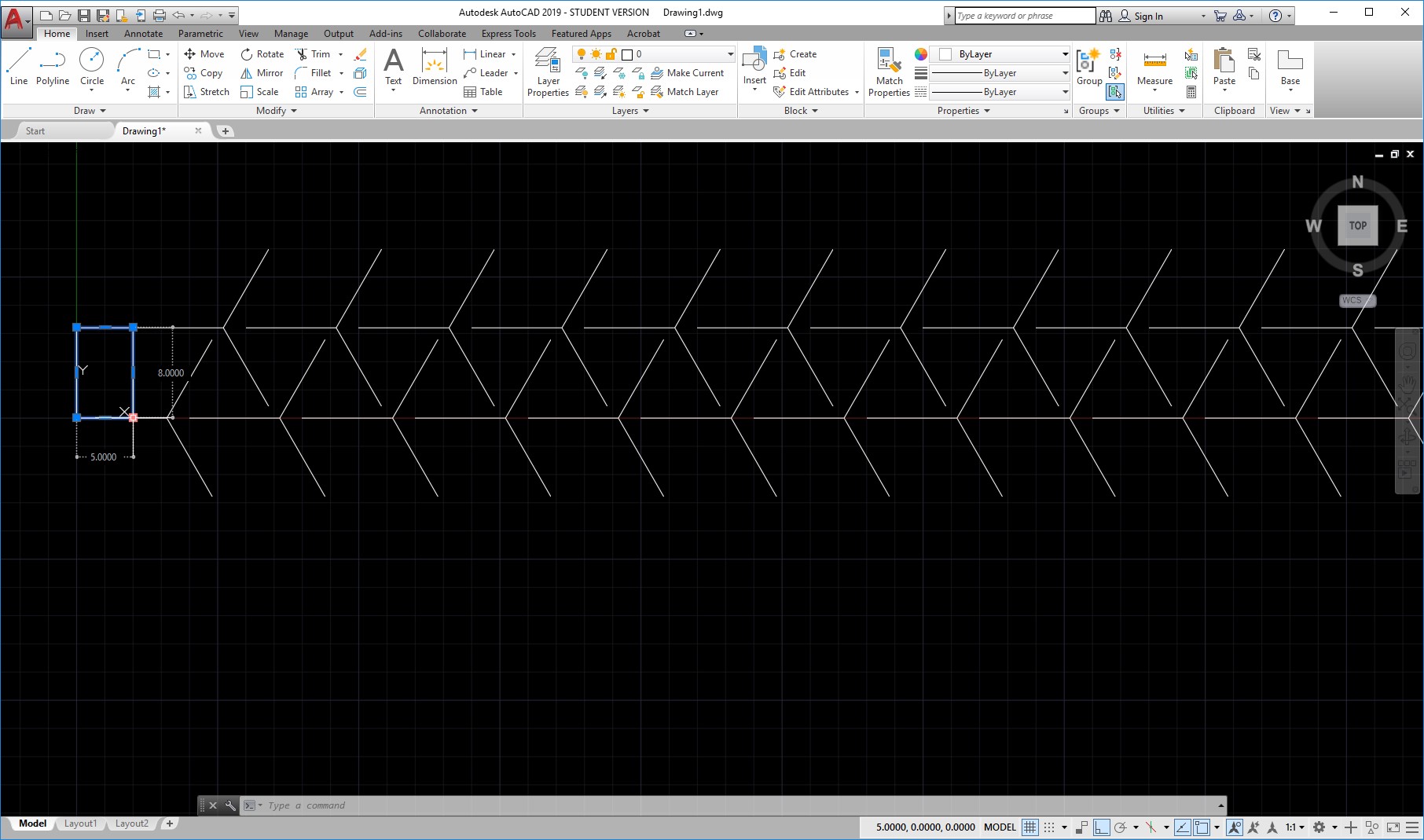

So I begin printing. In the mean time, I will design a pattern to laser cut in foam sheets. Fot this, I used autocad. I begin with a 8 mm horizontal line.

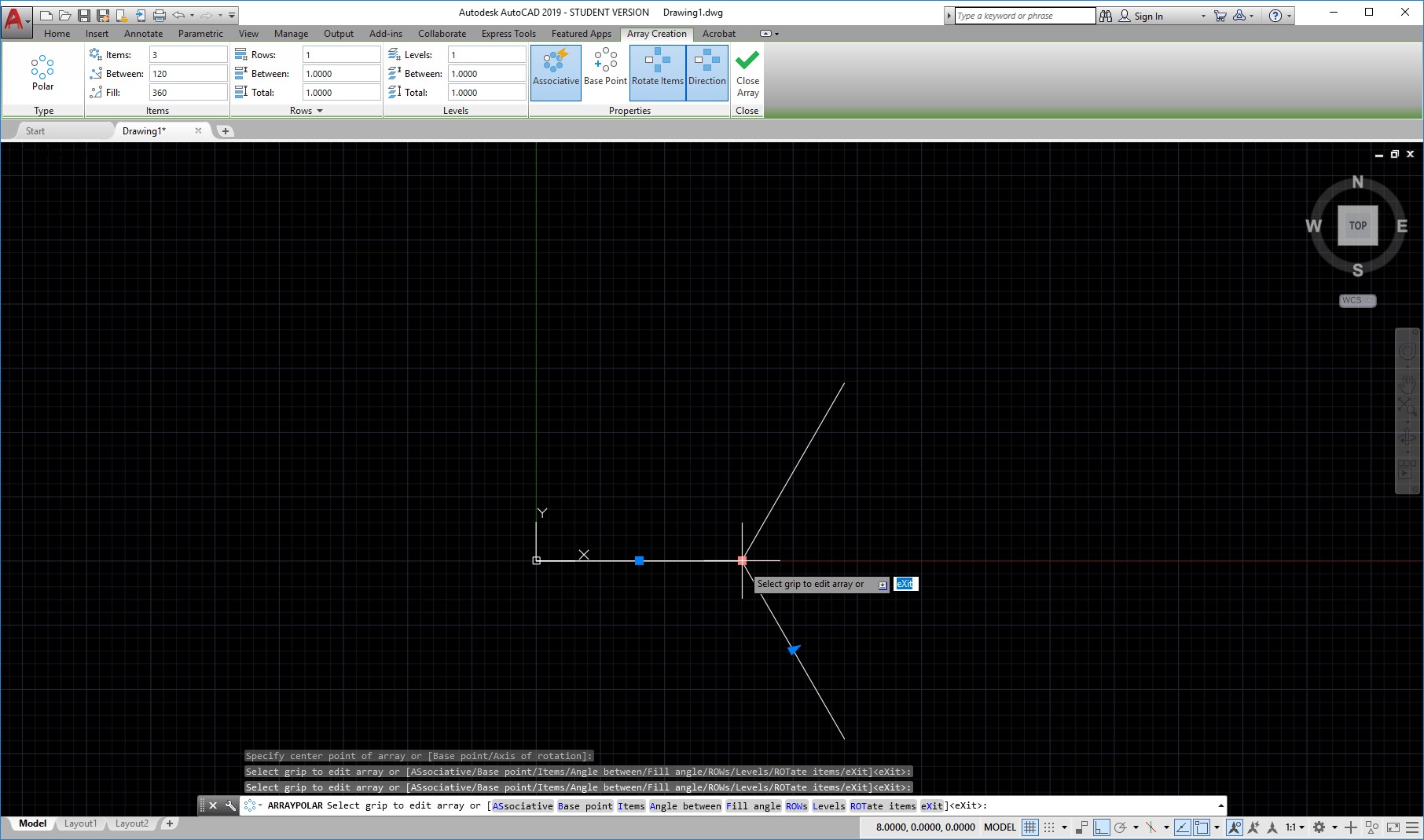

Then, I will do a polar array, with 3 element rotating at the end point of the line, as shown below.

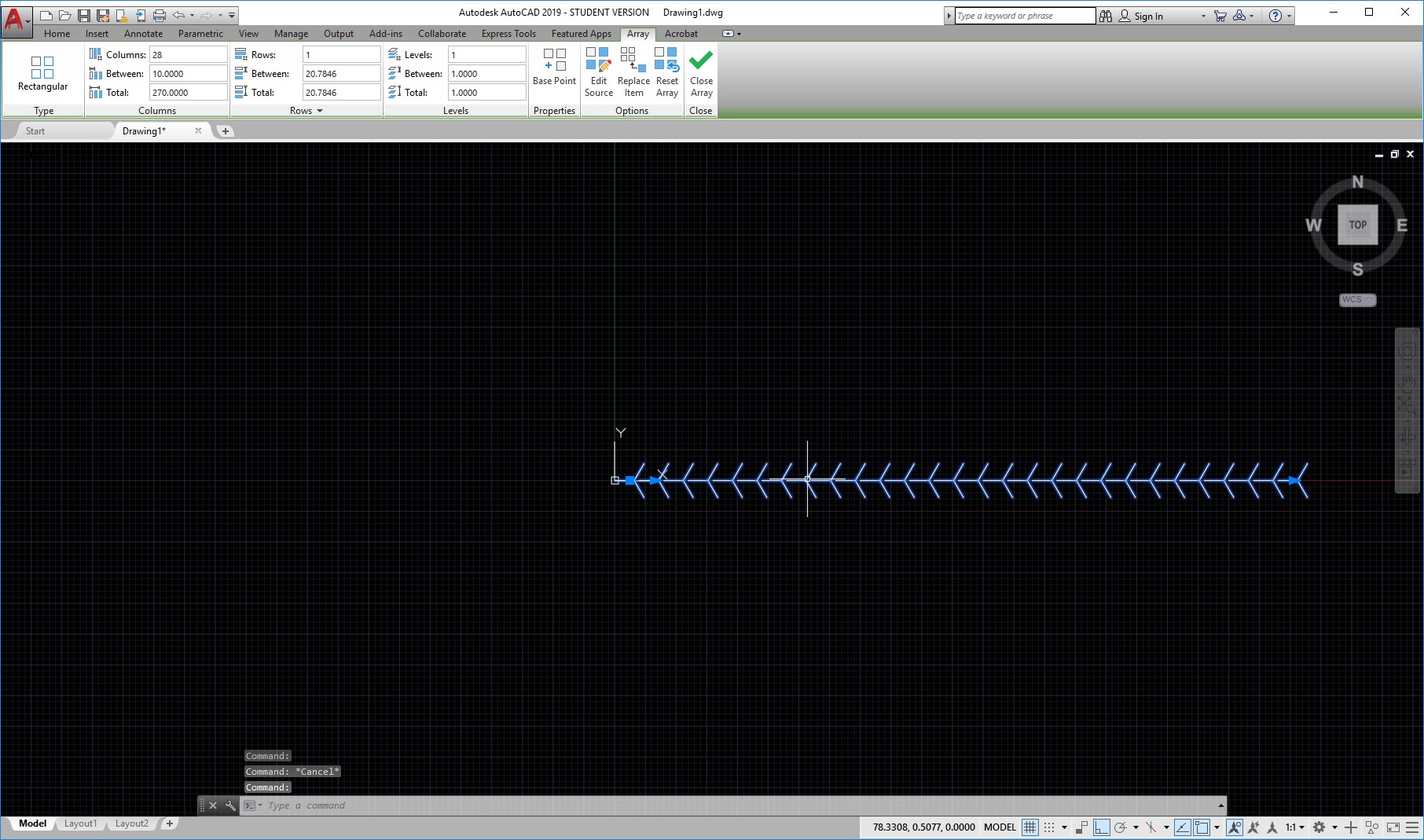

And now a linear array, in the x axis, with a separation of 10mm.

Now, I will copy the patern, and move it 8mm in the y axis, and 5 in the x axis

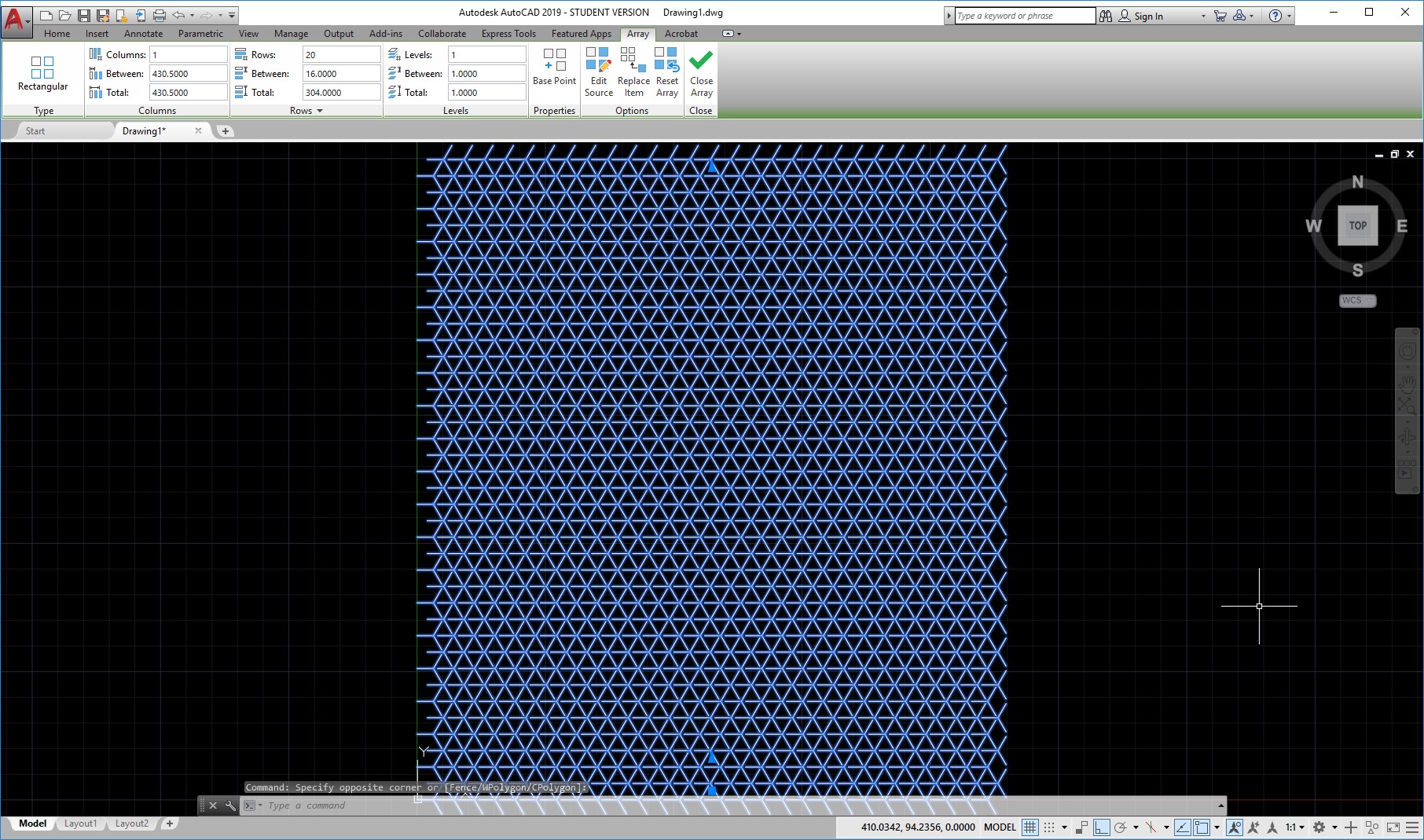

And finally, I will replicate this in the y axis spaced at 16mm.

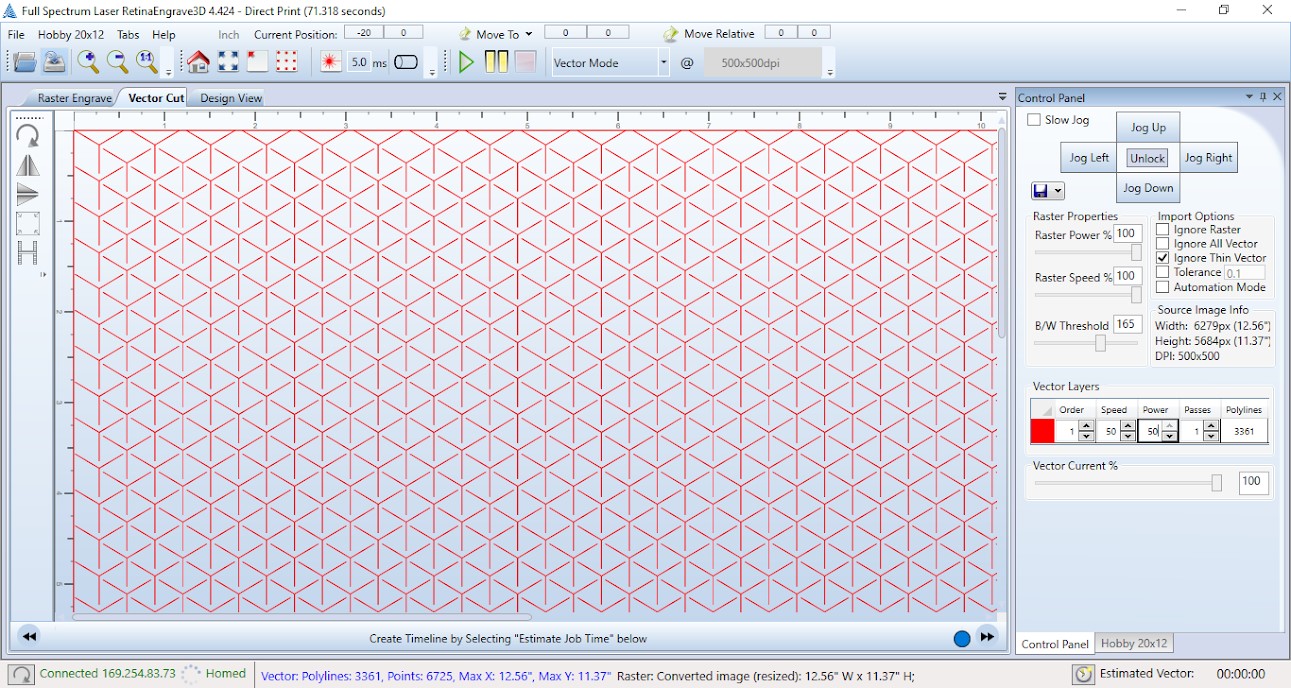

Now, I will save this as pdf, and laser cut it using the fullspectrum machine. But I will use a power setting so that it doesn’t go through the foam. In this case 20%.

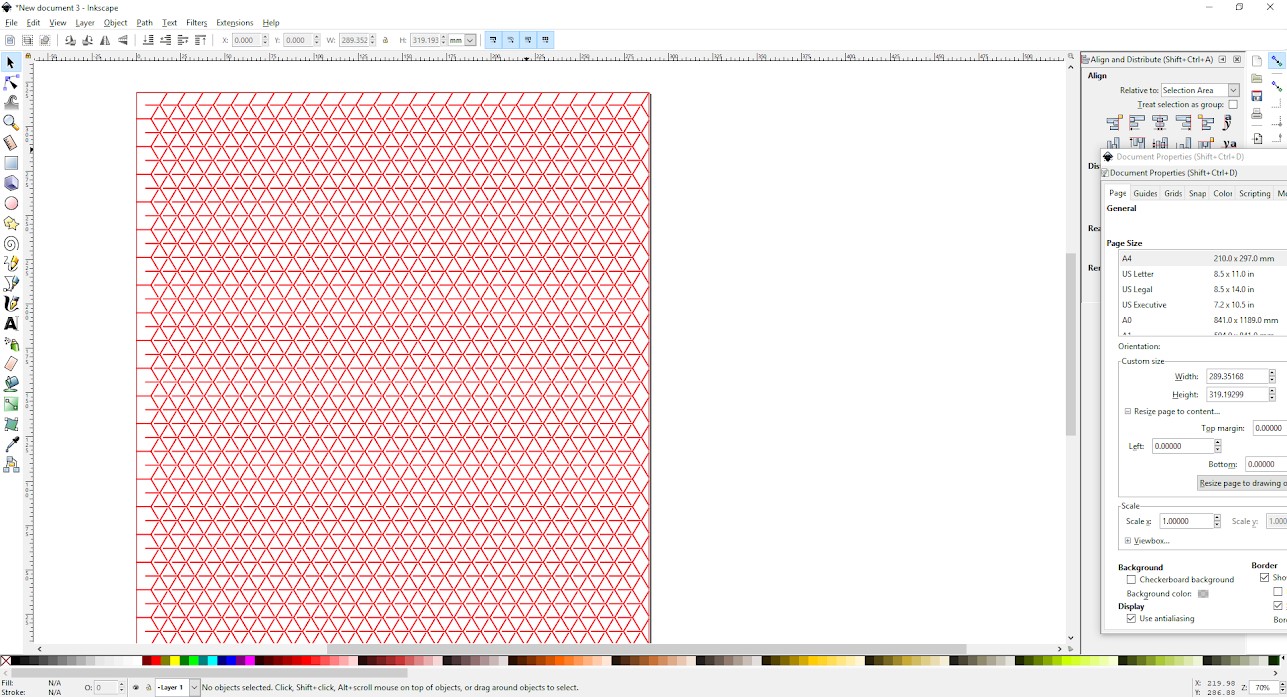

To cut it, I begin by opening the dxf file in inkscape:

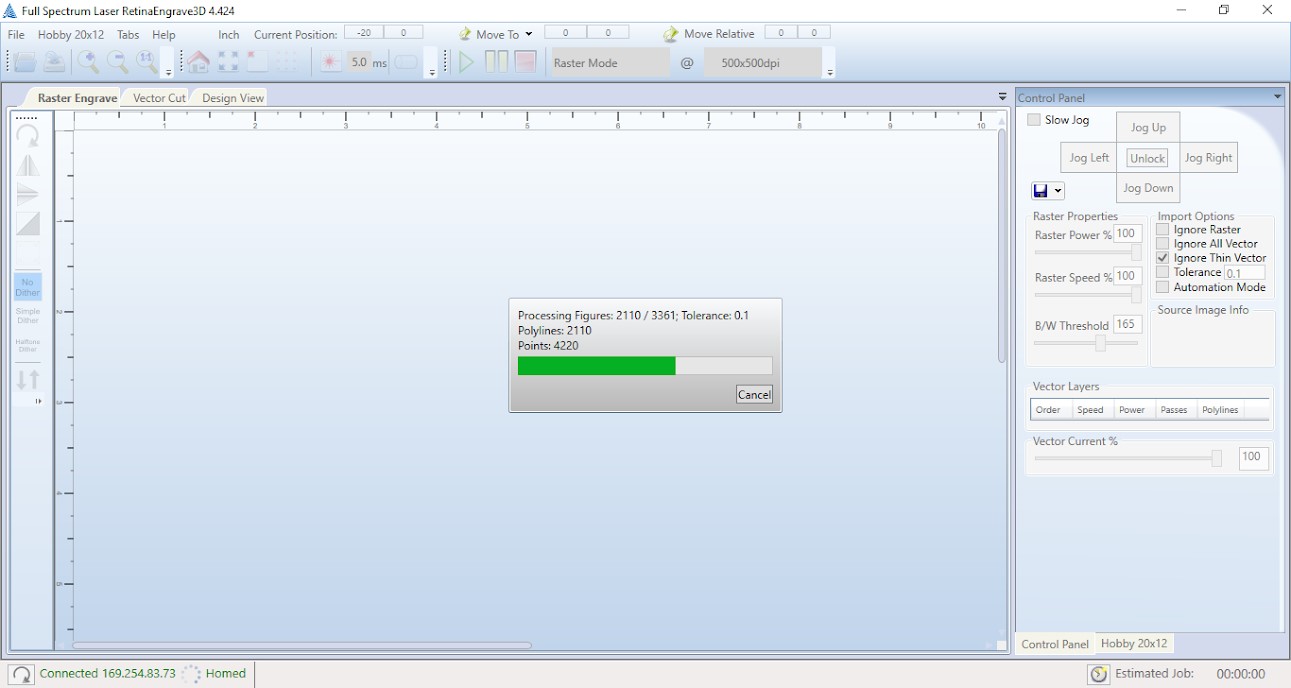

and then send it to print to the full spectrum software. Because there were so many lines, this tooko a few minutes.

but it finally open

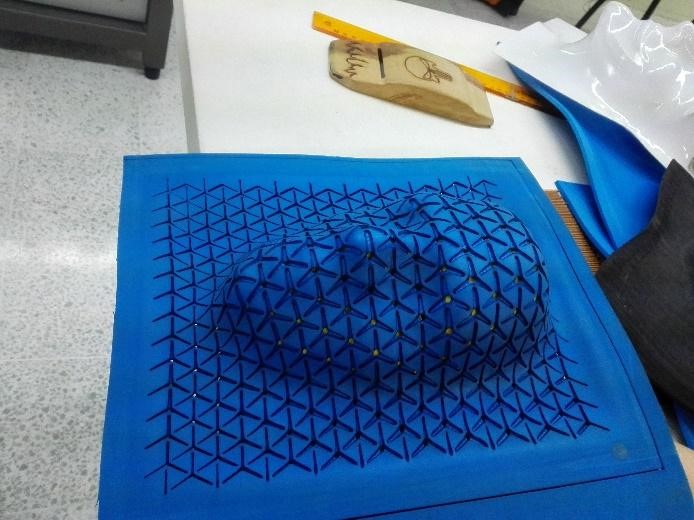

and after sending to the machine, this is the result

i used also cardboard material to make the pattern

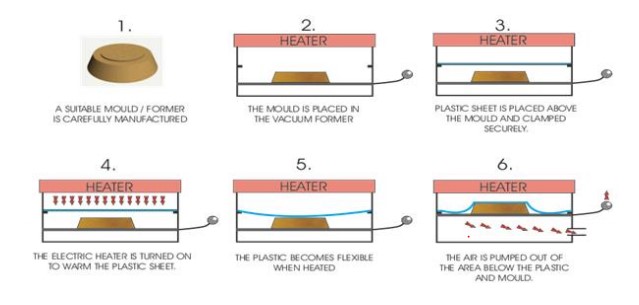

The new process I will try this week is vacuum forming. This consist of heating up a material to 110 degrees until its in a transition phase when I will be molded, and then its forced into a mould, and vacuum is applied to make it copy the form and cool down.

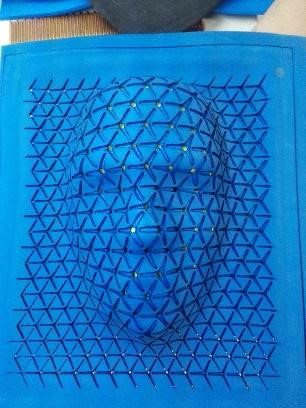

The material I will use is sheets of 3mm foam, but before vacuum forming them, I laser cut it to give it a texture. The mold I used is 3d printed, and the final product is a mask with a very nice pattern, as shown below:

This works as a textured mask that can be replicated much faster because the vacuum forming process takes only 2 minutes, while 3d printing takes more than 7 hours. Vacuum forming is a very good way of making many replicas of the same part, But because it's done with heat, you need to wait for a few minutes before doing it again as the 3d print could begin to deform.

The purpose of this week is to try something else not included during the schedule of fab academy, and this is why I used vacuum forming as a process, combined with 3d printing and. Laser cutting. The result was even considered art by some of the visitors of the lab.

Download File: Pattern.pdf

Download File: Pattern.dxf

Download File: Face_Mask